1

/

of

3

ESP

ESP

Share

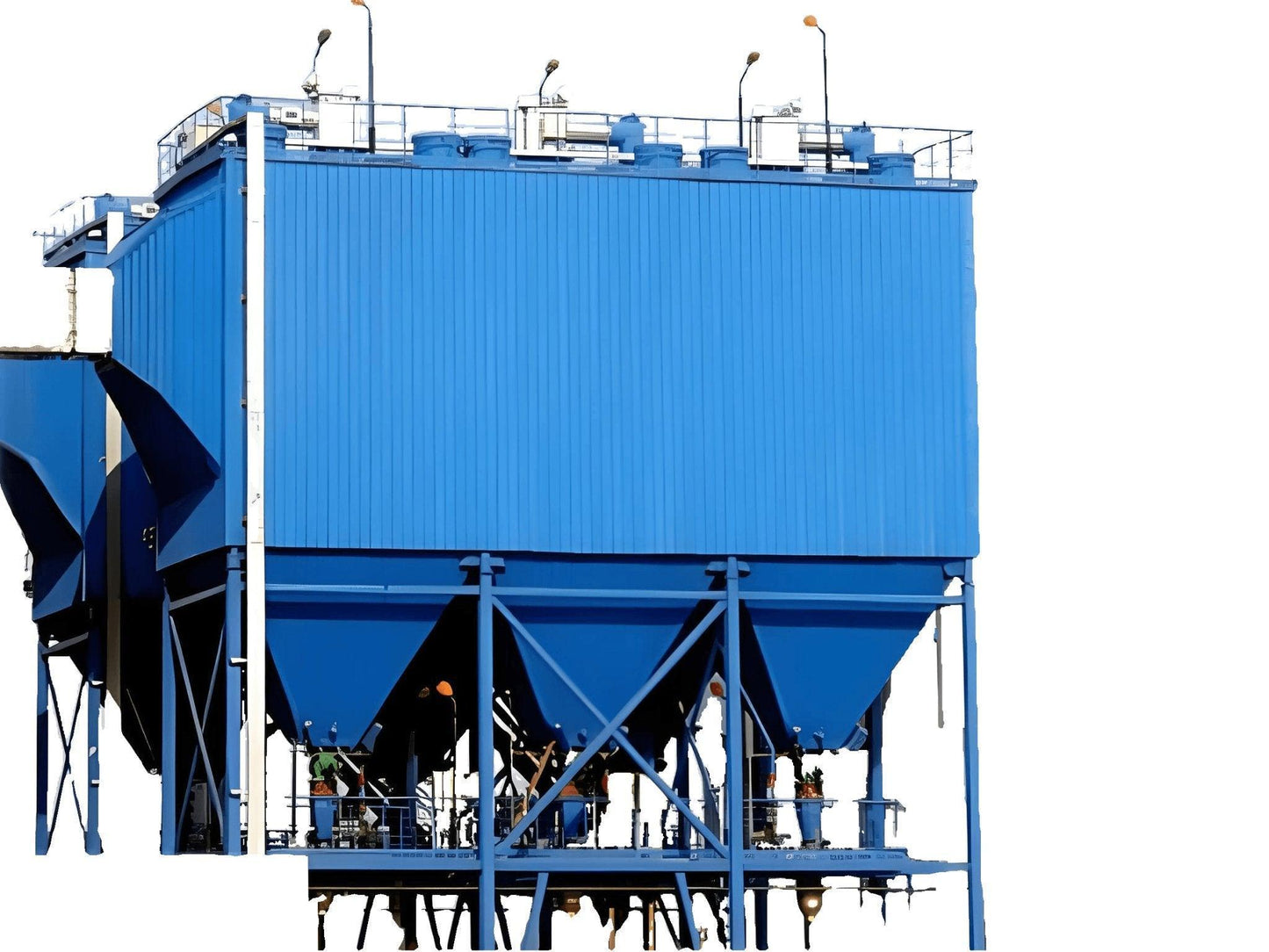

An Electrostatic Precipitator (ESP) is a highly efficient air pollution control device that removes particulate matter from a gas stream using electrical energy. It is widely utilized in various industries, including power generation, cement manufacturing, and chemical processing, to improve air quality and comply with environmental regulations.

Key Features

-

High Collection Efficiency:

ESPs can achieve collection efficiencies exceeding 99%, effectively capturing fine dust and smoke particles. -

Operation Mechanism:

The ESP works by charging particles in the gas stream as they pass through discharge electrodes, creating ions that attach to the particles. These charged particles are then attracted to oppositely charged collection plates. -

Types of ESPs:

There are two main types: dry ESPs, which use mechanical rapping to remove collected dust, and wet ESPs, which wash the dust off with water. -

Durability and Maintenance:

Constructed from robust materials, ESPs are designed to withstand harsh operating conditions. They require periodic maintenance, primarily focused on the rapping system and electrical components. -

Customizable Design:

ESPs can be tailored to meet specific operational requirements, including different gas flow rates and particulate characteristics.

Working Process

- Gas Inlet: Contaminated gas enters the ESP through an inlet.

- Charging Particles: As the gas flows through, particles are ionized by high-voltage discharge electrodes.

- Collection of Particles: Charged particles are attracted to collection plates, where they accumulate.

- Dust Removal: Collected dust is periodically removed either by mechanical rapping (in dry ESPs) or water flushing (in wet ESPs).

- Clean Gas Outlet: The cleaned gas exits the ESP, significantly reducing airborne particulate emissions.