1

/

of

4

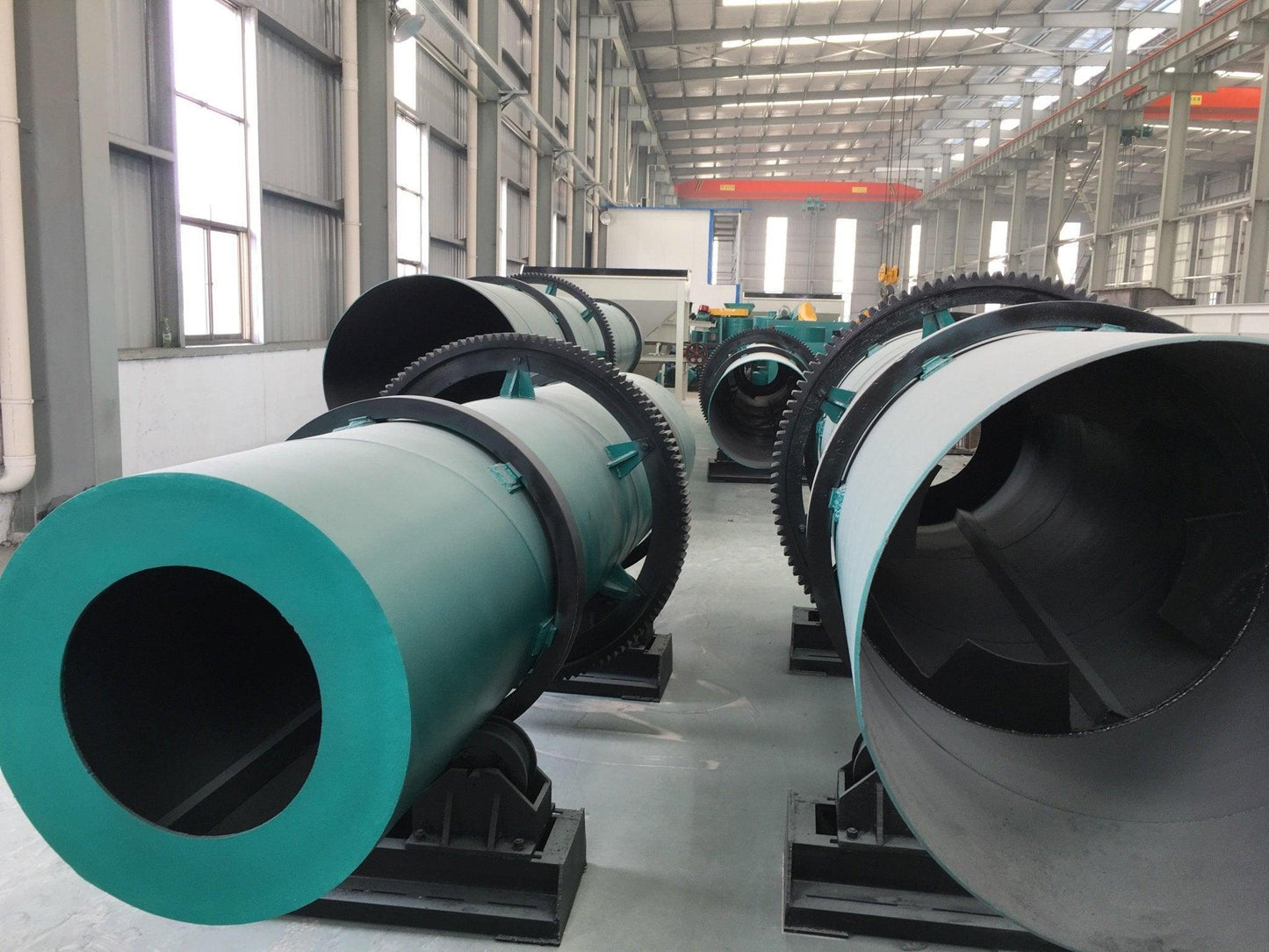

Drum Dryer/Cooler

Drum Dryer/Cooler

Share

A Drum Dryer/Cooler is an industrial machine designed for drying or cooling bulk materials through a rotating drum mechanism. This equipment is widely used in various industries, including food processing, minerals, and chemicals, to efficiently manage moisture content and temperature of materials.

Key Features

-

Dual Functionality:

The drum can be configured for both drying and cooling processes, allowing for versatility in operations. -

High Throughput:

Capable of processing large volumes of material, the drum dryer/cooler is ideal for high-capacity operations. -

Efficient Heat Transfer:

In drying applications, hot air or combustion gases are introduced to evaporate moisture, while in cooling applications, chilled air is used to reduce material temperature. -

Robust Construction:

Built with durable materials to withstand harsh operational conditions, ensuring long service life and reliability. -

Adjustable Settings:

Features adjustable parameters such as temperature and airflow to optimize performance for specific materials.

Working Process

- Material Feeding: The material is fed into one end of the rotating drum.

- Drying/Cooling Action: In the case of drying, hot air flows through the drum, while in cooling, chilled air is introduced. Lifting flights within the drum help move the material and enhance contact with the air flow.

- Discharge: The processed material exits at the opposite end at the desired moisture content or temperature.